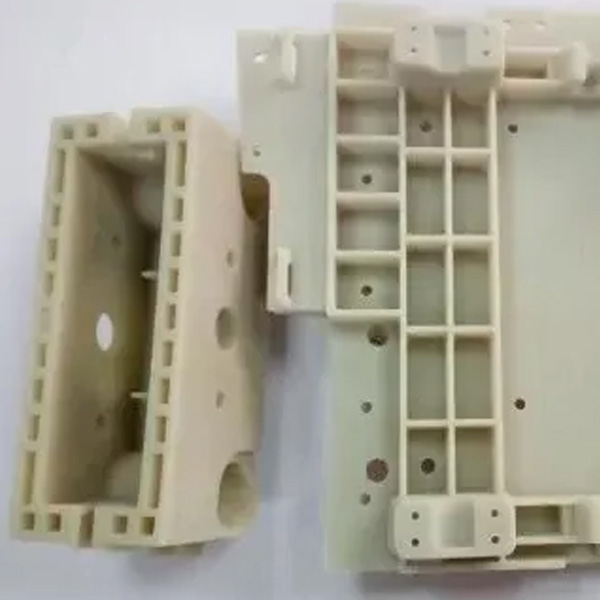

Case of Internal Reinforcement of Smart Game Console

According to your project needs, CNC service can solve various problems for you. If you would like to know more about technology and prototyping services, please call us. We are glad to provide you with professional and efficient service.

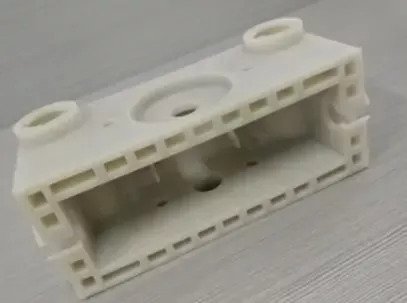

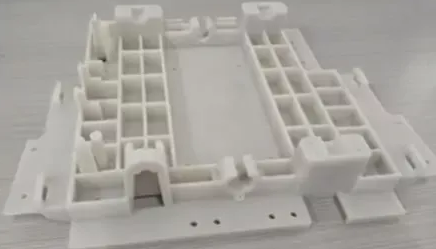

- Material Used:PA+30%GF

- Number of Cooperation:8 sets, 24 parts in total

- Production Process Used:SLS 3D printing technology

- Production Cycle:7 days

Project Details

About Product and Design Requirements

This part is used for the main part of the aircraft driver operation in the intelligent game simulation to withstand strong impact, sliding friction and bearing assembly, so it must be produced strictly according to customer requirements, including:

- Dimensional tolerance request customer

- Material application

- Professional production technology team

- Fast delivery

Customer Demand

Ryder high-end manufacturing company attaches great importance to product manufacturing technology and uses the latest cutting-edge production methods. Their philosophy is to create high-quality products for customers. They recently asked us to provide support in order to prototype them.

About the Project

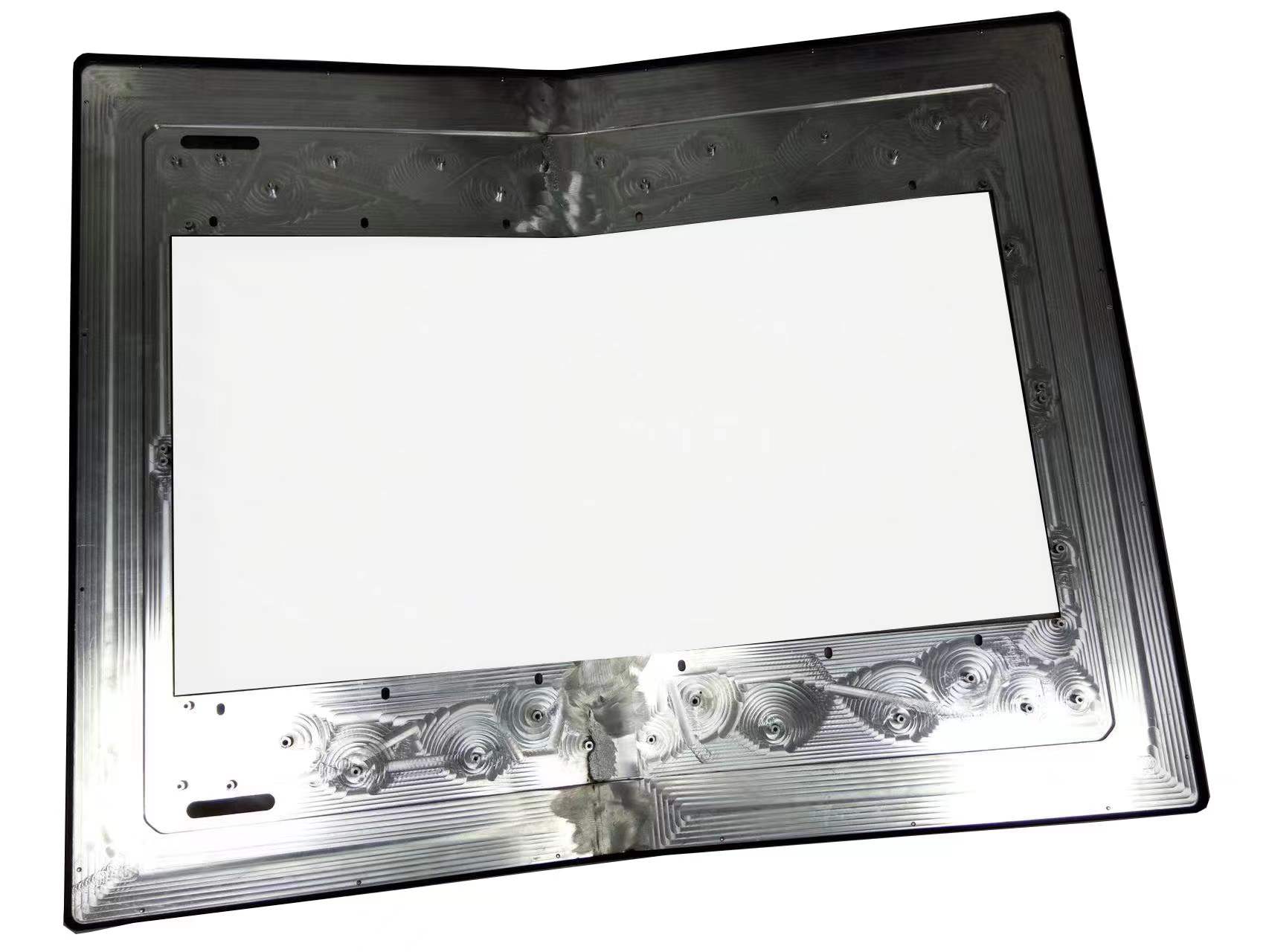

Before cooperating with HY PROTOTYPE, the customer had done a number of tests on the internal parts of the smart game, and the customer was not satisfied with the application of the material. We have found that we can help customers solve problems in the materials and production process of internal parts. Our company’s engineering and technical personnel determine the final material PA + 30% GF by analyzing the customer’s previous test results. Through a comprehensive review of the delivery date and production cost, we use SLS 3D printing technology. This method is a cost-effective production process that can shorten the product development cycle.

SLS Process Introduction

After selective laser sintering is controlled by a computer, the plastic powder is cured by laser, but the metal powder is not cured layer by layer through selective curing. SLS is easy to process, fast, and can use a variety of materials. In principle, this method can be used to heat any powder material that reduces the viscosity, and the particles can be formed into any shape through this material or various binder coatings to suit different needs.

High precision. Depending on the type of material used, particle size, product geometry, and complexity, the process can usually reach a tolerance of +/- (-0.05-2.5) mm over the entire range of the workpiece. When the particle size of the powder is less than 0.1mm, the accuracy of the prototype after molding can reach plus or minus 1%.

Experience

The most fundamental reason why we can satisfy our customers is the support and application of new technologies, and they have very good cost performance. If you happen to have a project to solve, please contact us in time, you can get free professional analysis and cost control.