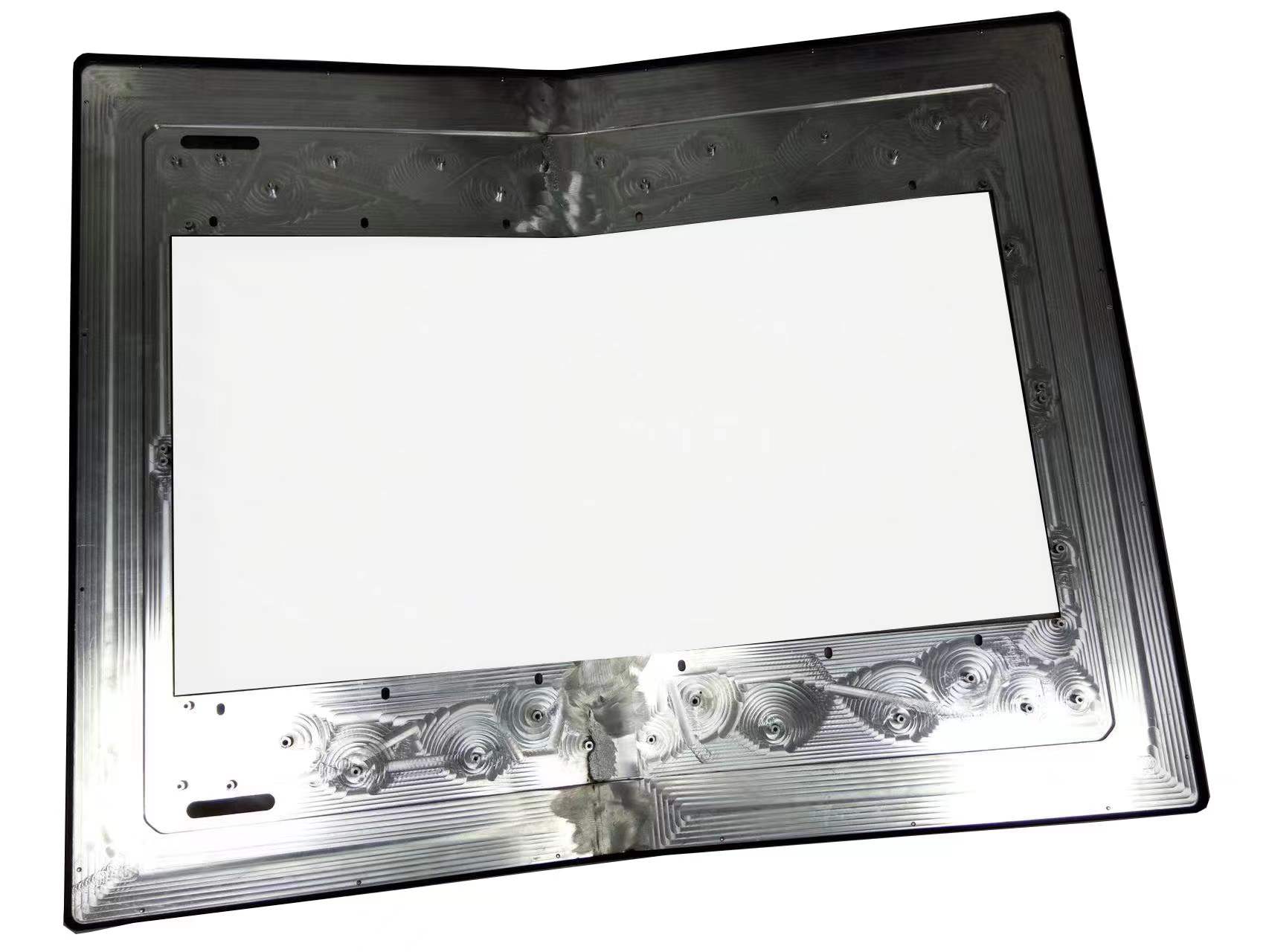

CNC processing prototype for wagering equipment

HY could help you to save cost on the early stage of development of new products and have more competition on the market, Our engineers find out the way to improve the processing method in order to achieve cost control.

- Material Used: Aluminium 6061 T6

- Number of Cooperation:1 set

- Production Process Used: CNC Machining

- Production Cycle:7 days

Project Details

What HY could help you on Prototype with CNC Processing?

The client is one of the most famous suppliers for Gaming and Wagering equipment in the world.So they have huge input on the design and production for new products. They purchased this part from the other company before, as the result, the cost is very high and they did not get a achievable improving way to reduce it , then they looked for new supplier and found our company via Google.

HY Prototype could process various metal and plastic parts for you with various CNC machining services, including milling, turning, EDM, wire cutting, surface finishing, and so on. Using our advanced 3-axis, 4-axis, and 5-axis CNC machining centers, our skilled machinists can use a variety of plastic and metal materials to manufacture turning and milling parts. We provide satisfactory and excellent one-stop service for your prototyping.

Welcome to contact us for a quotation and discuss the best solution for the project together.

Case introduction for this part with CNC maching:

1.Parts requirements:

Dimensions: 1150x758x65 mm

Thickness: 2.5mm

Material: AL 6061 T6

Accuracy requirements: dimensional accuracy +/-0.15-0.2 mm maximum deformation 2mm

Other requirements:

1). The appearance surface is smooth and there should be no processing marks;

2).The surface needs to be Electrostatic sprayed.

3).Compliant with ROHS/REACH

2.Parts information and usage:

As our research with client for the parts usage,This part is used for the surface panel and the inner side need to install the Liquid crystal display and streamer light guide assembly.

The part need to support the impact of external force to ensure that the internal electronic equipment will not be damaged.

The reason of the high production cost: The part size is large,and the high requirement of precision and deformation is very high.

As the early stage of small batch production(20-50pcs),so the processing method is CNC maching.

Our Production cost reduction plan:

Our technical team made a specific plan to help our client to reduce the cost via the follows:

- The precision is the most important matter for the production cost. So We Subdivide part tolerances of the part, to ensure the assembling size with +/-0.15-0.2mm, the other size tolerance to +/-0.3mm.

- As the quantity of parts,we still use CNC processing and improve it.

- To reduce the raw material cost, we divide the part to three parts for processing. The size will be smaller and the CNC machines could be adopted the middle types to save the processing cost.

- We use the special jigs to control the Deformation and welding strength. so as to produce more parts per unit time and reduce production costs.

With above methods to reduce the cost perfectly and ensure the parts are assembling.

- The cost of raw material- aluminum, was reduced 50%.

- The processing cost by changing the equipment, was reduced 50%.

- The production efficiency is upgraded by 30% with the 3 parts processing.

The former processing way: 1 set CNC could process 1 part by 48Hours.

The current processing way:1 set CNC could process 1.5 parts by 48Hours

Totally the cost is well reduced 25%-30% than before. The client is very satisfied with our work and have more deep cooperation with us to have win-win business.

If you have the similar problem on production cost. Welcome to contact us with your drawings and information, We are glad to help you to have a solution to saving your cost and improve the processing method.