Jewelry Identification Mirror Case

According to your project needs, CNC service can solve various problems for you. If you would like to know more about technology and prototyping services, please call us. We are glad to provide you with professional and efficient service.

- Material Used:PMMA

- Number of Cooperation:30 sets total 30

- Production Process Used:CNC turning, CNC milling, Surface plating

- Production Cycle:15 days

Project Details

About Product and Design Requirements

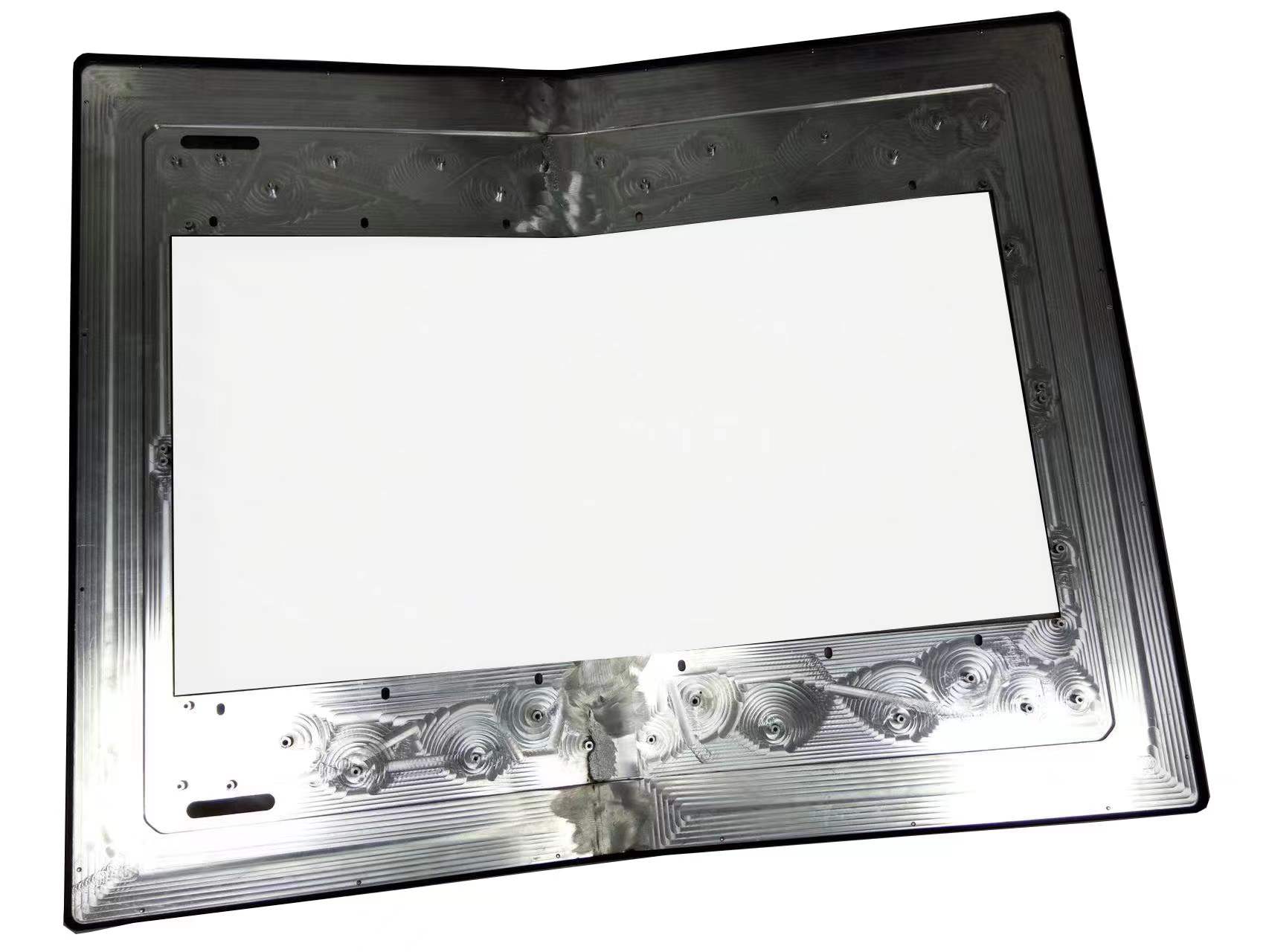

This product is used to measure the glossiness of jewelry according to the principle of light refraction and reflection. Therefore, the requirements for the inner and outer surfaces of the product are:

- Finish all mirror processing.

- There must be no scratches on the surface.

- The angular size of each product requires processing accuracy, the light transmittance of the material must reach 95% or more, and the key technology is the partial electroplating product.

Design Analysis

Take a closer look at the design

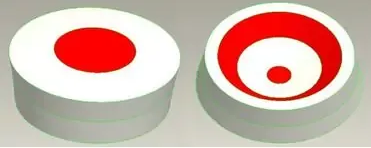

1. The white parts required by the customer need to be fully reflective mirror plating, and the red area needs to be completely transparent. The product is completely customized according to customer needs. The material we choose for customers is PMMA. In the follow-up process of polishing and partial plating technology, we have professional Prototype manufacturing technology, which can well meet customer needs.

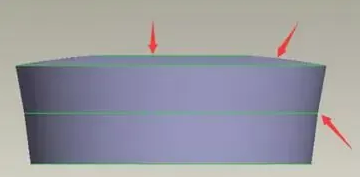

2. The arrow in the figure has a small angle. If the process does not meet the requirements of the machined surface, and the surface boundary is blurred, the overall shape of the product will be different from the original design. This is the most undesirable result for customers. We must deal with detailed technical experience to fully meet customer requirements.

Detection Method

Our QC department uses a three-coordinate measuring instrument to measure the actual size of the processed parts to check the consistency of the entire batch of parts to ensure compliance.

About the Project

The key is to understand the size of the customer's product and the ultra-high requirements of the product surface. Our manual post-processing team provides professional technical support. Through sample production and testing, so that customers can meet their requirements.

CNC turning

We use CNC turning processing to ensure the perfection of various detailed features.

Post-processing

Polishing is an important part of the entire product processing process. We divide it into four steps to ensure the gloss consistency of each surface. Finally, mirror polishing. The entire process must be a coherent whole.

The last step is electroplating. Customers need partial plating. We use the immersion method for electroplating, and add production line technology between the electroplated surface and the transparent surface to ensure the perfect connection between the electroplated surface and the transparent surface.

Experience

We are proud of every part we do. You will be proud of having these customized parts. In the production process, we will seriously sum up our experience in order to provide you with comprehensive customized services to meet the needs of each customer. When you have a solution or need customized needs, we are ready to provide you with customized perfect services.