High-end Luxury Bentley Car Air-conditioning Vent Outer Ring And Other Car Accessories

According to your project needs, CNC service can solve various problems for you. If you would like to know more about technology and prototyping services, please call us. We are glad to provide you with professional and efficient service.

- Material Used:304 stainless steel

- Number of Cooperation:5 batches per year, 50 pieces per batch

- Production Process Used:Three-axis CNC turning pin processing, four-axis CNC milling processing, mirror polishing post-processing

Project Details

Cooperation Premise

This is a successful case of cooperation with international high-end customers. The customers come from the Volkswagen Bentley brand in the automotive industry.

Before the cooperation, these parts were produced by another company. However, due to the high requirements of customers on the structural dimensions of the product, product deformation, and especially the external surface treatment technology, the other company did not meet the standard in the surface treatment process in the sample confirmation.

In suitable conditions, we have obtained the qualification for sample confirmation. Through the full-scale detailed communication between our engineers and customers, and our understanding of product positioning, the samples have been recognized by customers.

Because it is small-batch production, the customer's requirement is that the cost must be controlled to the lowest range and delivery must be completed quickly.

About the project

Through cost accounting and process analysis, we combine CNC turning + four-axis CNC milling + 16-process post-processing. After various supplier evaluations, the customer finally chose to cooperate with us.

CNC turning processing

During the machining process, we have solved the SUS304 material's high hardness, easy to wear tools, and easy deformation during machining, so that the accuracy of the parts is well controlled within the design accuracy range.

CNC milling processing

The four grooves of the outer ring of the part are an important feature of assembly. We use four-axis CNC machining technology to ensure the accuracy of the groove angle and step height.

Surface treatment

Surface treatment directly affects the high-end of the overall appearance of the car. We use 16 processes to mirror the surface of the product.

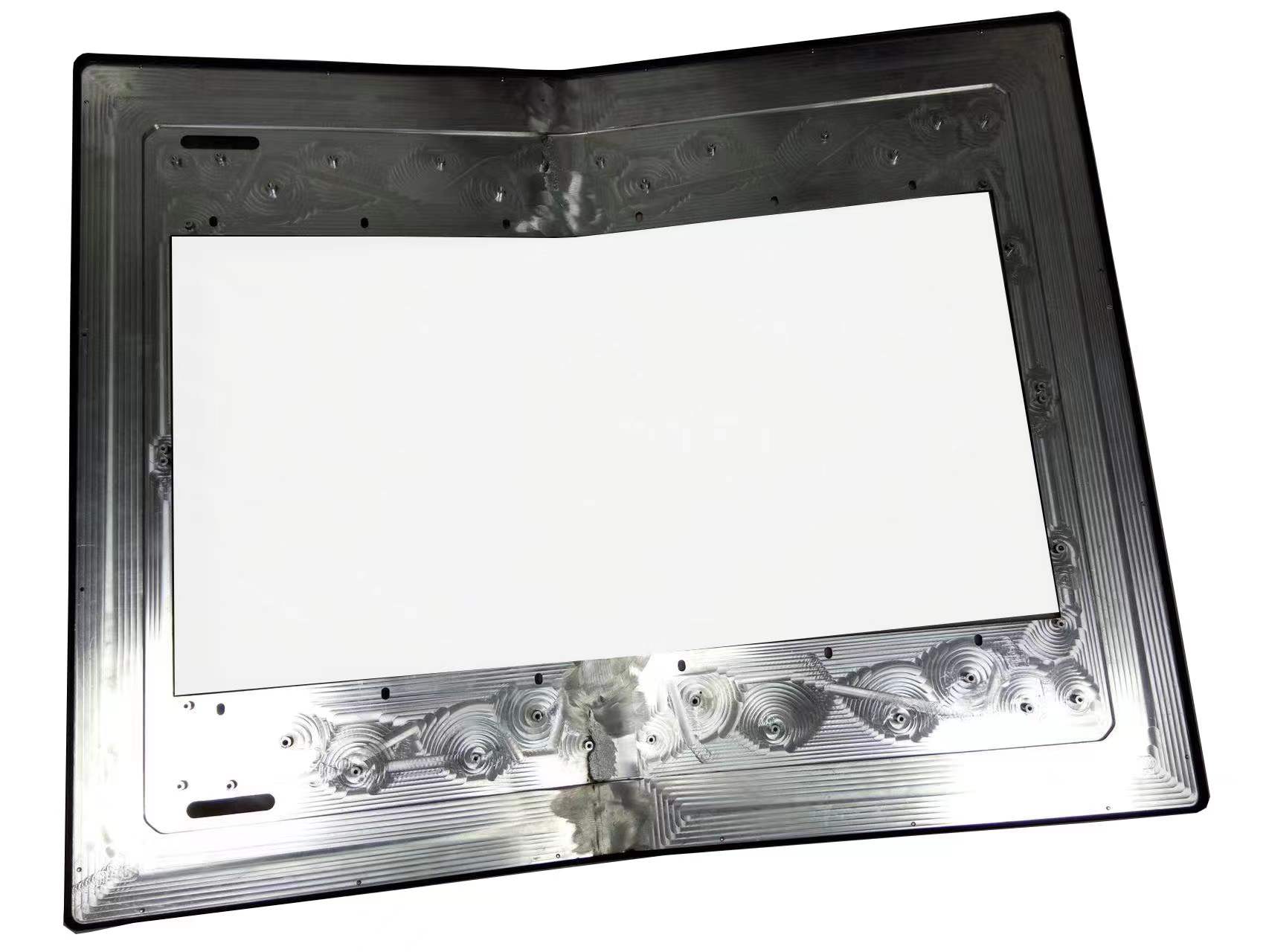

Actual loading effect drawing

Quality Inspection

Dimensional accuracy inspection: Our QC department uses a three-coordinate measuring instrument to measure the actual size of the processed parts to check the consistency of the whole batch of parts to ensure that they are qualified.

Product appearance inspection: We have a professional light source box inspection and pass the 360-degree gloss inspection to ensure that there are no fine scratches and wavy lines on the surface.

Parts protection measures

The first layer protects the outer surface of the product, the second layer protects the parts from bumps, and the third layer protects the parts from extrusion and deformation.

Experience

We have mature processing schemes and refined craftsmanship, a full understanding of products and customer requirements, and advanced inspection equipment, and strict inspection standards so that customers can trust us and satisfy customers!

If you happen to have a project to solve, please contact us in time, you can get free professional analysis and cost control.